The Ultimate Guide to Neodymium Magnets Rare Earth Magnets in 2023

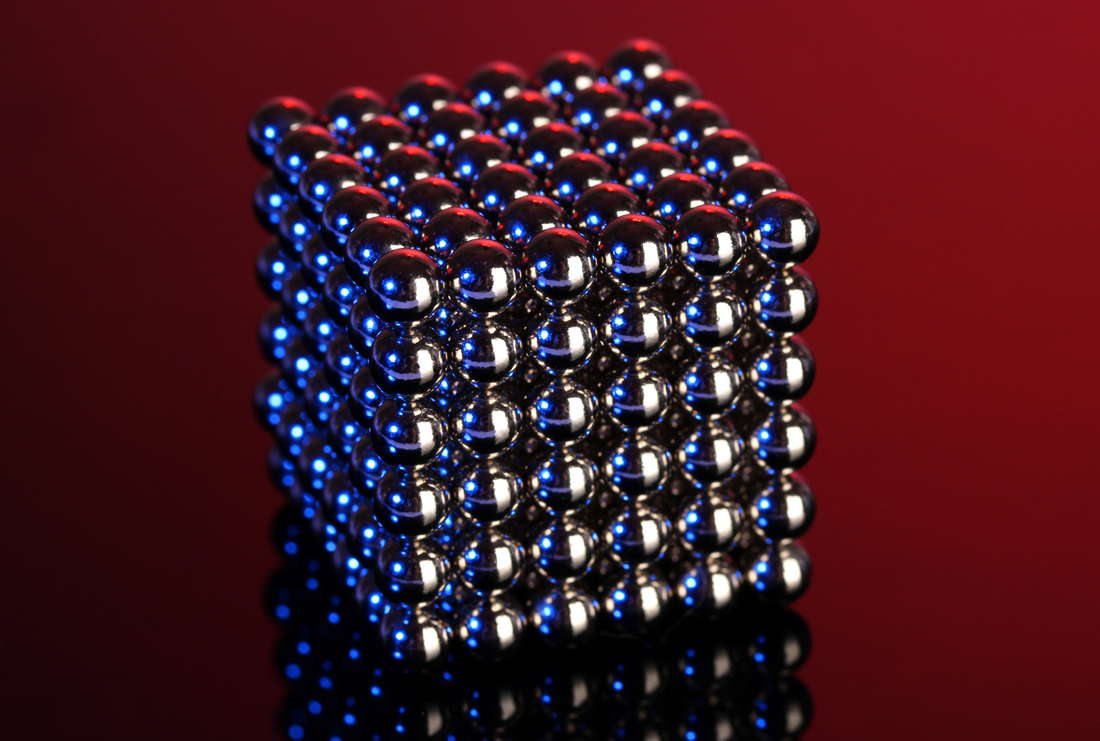

If you haven’t already heard of neodymium magnets, they are the strongest type of permanent magnets available!

They are a part of what is known as “rare earth magnets” and due to their strong magnetic properties, superior performance and relatively low cost, they are very popular today and are used in everything from industrial and commercial applications to jewelry-making and dentures.

In this post, we’ll take a deep dive into the world of rare earth magnets and discover what neodymium magnets are, their benefits, uses, magnetic grades, history, FAQs and more!

Table of Contents

- What are Neodymium Magnets?

- What are Rare Earth Magnets?

- Neodymium magnets vs Samarium Cobalt magnets

- Why are rare earth magnets called permanent?

- Does rare earth refer to scarcity?

- Rare earth magnets vs regular magnets

- History of Neodymium Magnets

- How Strong are Neodymium Magnets?

- How are Neodymium Magnets Made?

- Grades of Neodymium Magnets

- Uses for Neodymium Magnets

- Where to Buy Neodymium Magnets for Sale?

- Frequently Asked Questions on Neodymium Magnets

What are Neodymium Magnets?

Neodymium magnets, also known as Neo, NdFeB or NIB magnets are manufactured from an alloy of:

- Neodymium

- Iron

- Boron

They are called NdFeB magnets for this reason as well — Neodymium (Nd), Iron (Fe) and Boron (B).

Neodymium magnets come under the umbrella of rare earth magnets, which are permanent magnets with significantly stronger magnetic fields as compared to regular ceramic or ferrite magnets.

What are Rare Earth Magnets?

Rare earth magnets are magnets which are made from alloys of the rare-earth series of elements on the periodic table.

Neodymium magnets and samarium cobalt magnets are two types of rare earth magnets.

Both Samarium and Neodymium magnets are called rare earth magnets as they are found on the Periodic Table under the “Lanthanide” metal series, which belongs to the rare-earth family of elements. This also means their structures and properties are very similar.

Neodymium magnets vs Samarium Cobalt magnets

- Samarium is alloyed with the transition metal Cobalt = Samarium Cobalt or SmCo

- Neodymium is alloyed with the transition metal Iron and a tiny amount of Boron = Neodymium or NdFeB

What are the differences between NdFeB and SmCo rare earth magnets?

SmCo magnets can withstand higher temperatures and more corrosive environments. This makes them ideal for heavy-duty motors and railroad locomotives.

Neodymium magnets are known for their strong magnetic fields and are a lot more common and affordable. They are widely used in smartphones, sensors, and automotive motors where their small size coupled with their high-strength is a critical requirement.

Why are rare earth magnets called permanent?

Rare earth magnets are called “permanent” in the sense that they retain their magnetic strength once they are magnetized.

Does rare earth refer to scarcity?

Rare earth does not actually refer to being scarce. Neodymium is found abundantly in the Earth’s crust, and is more common than gold. The term “rare earth” comes from the unique geochemical characteristics of the element, and also because its usually dispersed and not concentrated in one location, making it harder to obtain cost-effectively.

Rare earth magnets vs regular magnets

The main difference between rare earth magnets and regular magnets are that rare earth magnets are made from rare earth alloys, whereas the standard magnets that we are most familiar with, are made mainly of iron.

| Rare Earth Magnet | Regular Magnet |

| Composed of rare earth elements such as neodymium, boron, iron (NdFeB) or samarium and cobalt (SmCo) | Composed mainly of iron oxide with nickel, barium, zinc and manganese |

| High magnetic energy | Low magnetic energy |

| High pull force | Low pull force |

History of Neodymium Magnets

As a rare earth element, with the atomic number 60 on the Periodic Table, neodymium was first discovered by Carl Auer von Welsbach, an Austrian chemist, in the year 1885.

Fast-forward to a hundred years later, and it took nearly a century for neodymium magnets to be developed.

In 1984, General Motors and Japan-based Sumitomo Special Metals invented neodymium magnets, when they discovered that a strong magnet was formed when they combined a small amount of iron and boron to neodymium.

This incredible discovery had a huge impact on the everyday technology we use today.

Neodymium magnets enabled electronic devices to be made much smaller, especially where a small magnet mass but strong magnetic fields were demanded.

Examples include, microphones, earphones, speakers, smartphones and computer hard disks.

Larger neodymium magnet applications include electric motors and aircraft generators where high power and low weight is required.

How Strong are Neodymium Magnets?

Neodymium magnets can be up to 10x stronger than the strongest ceramic magnets.

NdFeB magnets have a very strong magnetic field that surpasses 1.4 Teslas. In comparison, a regular ceramic/ferrite magnet can produce magnetic fields between 0.5 to 1 Teslas, with an average strength of 0.35 Tesla.

So, if you’re using regular magnets for a project, you can most likely use a much smaller neodymium magnet, and experience a much more powerful holding force.

Although ceramic or ferrite magnets are cheaper, when it comes to commercial applications, neodymium magnets have no match. They have high magnetization and also resist demagnetization. They are much harder than ceramic or regular fridge magnets, and less likely to break if dropped or exposed to stress.

How are Neodymium Magnets Made?

Neodymium magnets are made from an alloy of the elements neodymium, iron, and boron. The precise amounts of each element can differ, based on the strength required for a particular application.

There are two main ways neodymium magnets are manufactured:

Sintered neodymium magnets

A standard powder metallurgy process, the alloy is first heated in a furnace and cast into molds, then cooled to form ingots. The ingots are pulverized into a fine powder and pressed into molds and sintered (compacted to form a solid mass by heat/pressure). They are then cut, shaped, coated to prevent corrosion and magnetized.

Bonded neodymium magnets

Bonded neodymium magnets are formed by “bonding” the powdered alloy with a polymer binder. The mixture is then compressed, extruded or injection moulded to form a variety of complex magnet shapes.

The key difference between the sintered and bonded process, is that a sintered magnet is a stronger and more durable rare earth magnet, but costlier to manufacture. Bonded magnets are more cost-effective to manufacture and are also available in a variety of unique shapes.

Grades of Neodymium Magnets

N30, N35, N42, N52…This is typically what you’ll see when you look at the different grades of neodymium magnets available.

But what do they all mean?

In simple terms, the letter “N” stands for neodymium. The digits that follow refer to the magnetic strength of the magnet — the higher the number, the stronger the magnet, and the greater the magnetic field it will produce in any given application.

N52 neodymium magnets are currently the strongest and highest grade of neodymium magnets available in the market.

If there are any letters following the number, such as N40SH, it refers to the temperature rating of the magnet. Neodymium magnets without a letter following a number, such as N40 only, are at a standard temperature.

Depending on the needs of a particular application, you’ll find neodymium magnets for sale in a variety of grades, shapes and sizes.

Uses for Neodymium Magnets

Even if you haven’t heard of neodymium magnets, as the strongest permanent magnets around, there’s a good chance you use them every day!

Without this rare earth magnet, a lot of the advancements in technology that have happened over the last couple of decades, would not have been possible.

Uses for neodymium magnets include:

- Computer hard disk drives (HDDs) — These have tracks/sectors with cells that are magnetized when data is written to the disk

- Headphones, speakers and microphones — Coils that carry current, function alongside neodymium magnets to convert electricity to mechanical energy, thereby changing air pressure to create sound

- Door locks — Neodymium magnetic catches are used for greater holding force enabling increased safety and security in residential and commercial buildings

- Anti-lock brake sensors — These brake sensors use neodymium magnets inside their copper coils

- Home and office decor —Small neodymium magnets with a strong magnetic force work great for home, office, school, crafts, kitchen & the whiteboard.

- Dentures — Tiny neodymium magnets are used to keep dentures properly and safely in place

- Magnetic jewelry — Rare earth magnets are used to make magnetic therapy jewelry and also serve as strong clasps for bracelets and necklaces

The above list is just the beginning. Neodymium magnets are also used in:

- electric generators

- automotive engines

- power steering

- MRI scanners

- POI displays

- cordless power tools

- and much more!

Where to Buy Neodymium Magnets for Sale?

Looking for neodymium magnets near me? Neodymium magnets are available for sale online and in many retail superstores such as Home Depot, Lowes and Walmart.

These heavy-duty magnets are great for your office, kitchen, garage, classroom, living room, and DIY projects.

Frequently Asked Questions on Neodymium Magnets

Why are neodymium magnets coated or surface-treated?

Due to having iron in their composition, neodymium magnets will rust if left exposed to the elements. To protect from corrosion and to strengthen and support the magnet, a coating is applied.

There are many options for coatings available, out of which nickel is most commonly used. Other options include zinc, copper, tin and even precious metals such as silver and gold depending on the application the magnet is being used for.

What safety measures should be taken when handling neodymium magnets?

Neodymium magnets are hard, somewhat brittle, very highly magnetic, and snap together with considerable force. They may also chip if dropped on a hard surface or if they are allowed to “jump” towards other attracting magnets, so it’s important to handle them carefully.

How long can neodymium magnets last?

These magnets lose about 1% of their magnetic density over a decade, if they remain intact and are not influenced by demagnetizing forces such as temperature, radiation, other magnetic fields etc.

What are the characteristics of neodymium magnets vs rare earth magnets?

Neodymium magnets are a type of rare earth magnet, however they are far less susceptible to chipping and breaking, and much less costly as compared to other rare earth magnets such as samarium cobalt.

What’s the difference between an N35 and N52 magnet?

N52 neodymium magnets are about 50% stronger than N35 magnets. N35 magnets are less expensive and are used in applications where weight and size are not a major constraint.

Are N35 magnets strong?

Compared to regular fridge magnets, N35 magnets are relatively strong for their size. When compared to other neodymium magnets, they are a lower grade, and much less expensive.

In most cases, the highest strength N52 neodymium magnets not required for your project, and are much more expensive. For home and office projects, N35 magnets offer a great value.